Oxygen-free copper is typically specified according to the ASTM/UNS database [3]. The UNS database includes many different compositions of high conductivity electrical copper. Of these three are widely used and two are considered oxygen-free.

* C10100 - also known as Oxygen-Free Electronic (OFE). This is a 99.99%pure copper with 0.0005% oxygen content. It achieves a minimum 101% IACS conductivity rating. This copper is finished to a final form in a carefully regulated, oxygen-free environment. Silver (Ag) is considered an impurity in the OFE chemical specification. This is also the most expensive of the three grades listed here.

* C10200 - also known as Oxygen-Free (OF). While OF is considered oxygen-free, its conductivity rating is no better than the more common ETP grade below. It has a 0.001% oxygen content, 99.95% purity and minimum 100% IACS conductivity. For the purposes of purity percentage, silver (Ag) content is counted as copper (Cu).

* C11000 - also known as Electrolytic-Tough-Pitch (ETP). This is the most common copper. It is universal for electrical applications. ETP has a minimum conductivity rating of 100% IACS and is required to be 99.9% pure. It has 0.02% to 0.04% oxygen content (typical). Most ETP sold today will meet or exceed the 101% IACS specification. As with OF copper, silver (Ag) content is counted as copper (Cu) for purity purposes.

[edit] Oxygen-free high thermal conductivity

Oxygen-free high thermal conductivity (OFHC) copper is widely used in cryogenics. OFHC is produced by the direct conversion of selected refined cathodes and castings under carefully controlled conditions to prevent contamination of the pure oxygen-free metal during processing. The method of producing OFHC copper insures extra high grade of metal with a copper content of 99.99%. With so small a content of extraneous elements, the inherent properties of elemental copper are brought forth to a high degree. Characteristics are high ductility, high electrical and thermal conductivity, high impact strength, good creep resistance, ease of welding, and low relative volatility under high vacuum.[4]

Many cables today are advertised as using "oxygen-free copper," copper which has been annealed in an oxygen-free atmosphere. OFC is popular in audio cables, and has begun to make inroads into the video cable market as well.[5]. The merits of OFHC for such applications are, however, minimal.

Products > C10100 OFHC Copper

Material:

C10100 OFHC - Oxygen Free High Conductivity Copper

C10100 OFHC - Oxygen Free High Conductivity Copper

Need to send a drawing?

We are now accepting the following file types:

Quick Links:

Application:

Automotive - Automotive Rectifiers

Electrical - Transistor Component Bases, High Resistance-Ratio Cryogenic Shunts, Bus Conductors, Wave Guides, Hollow Conductors, Anodes for Vacuum Tubes, Coaxial Cable, Coaxial Tube, Klystrons, Microwave Tubes, Bus Bars, Lead-in Wire, Vacuum Seals, Conductors, Glass-to-Metal Seals

Copper Alloy C10100 has some typical uses in the electrical and electronic industries - bus bars, bus conductors, wave guides, hollow conductors, lead-in wires and anodes for vacuum tubes, glass to metal seals and others.

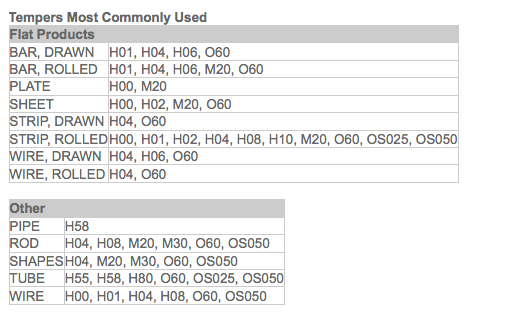

Available:

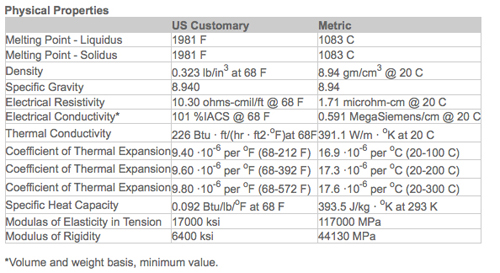

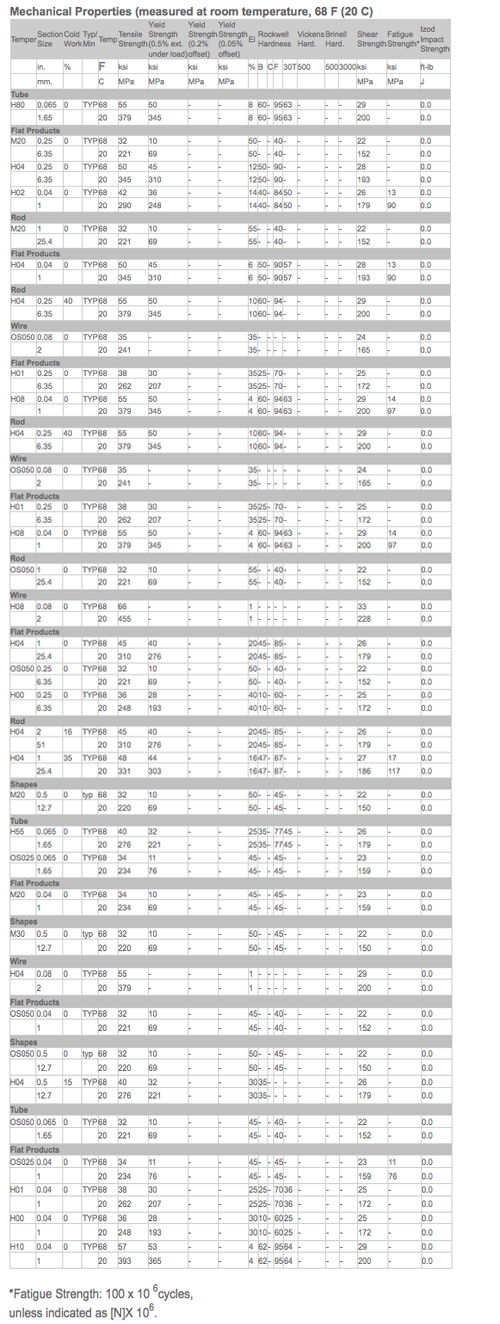

Properties:

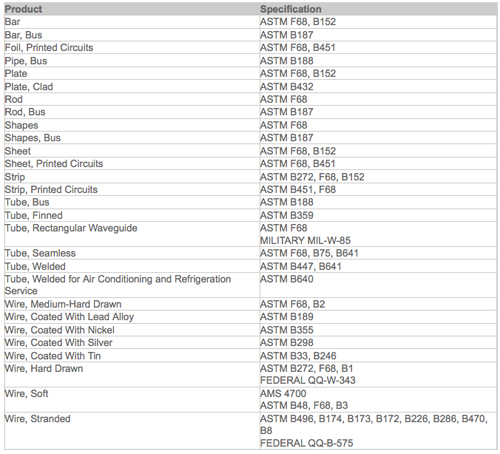

Applicable Specifications

the following information is courtesy www.copper.org

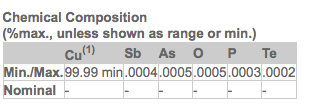

(1) Cu is determined by the difference between the impurity total and 100%. The Cu value is exclusive of Ag.

Note: This is a high conductivity copper which has, in the annealed condition a minimum concuctivity of 100% IACS except for Alloy C10100 which has a minimum conductivity of 101% IACS.

Note: The following additional impurity maximum limits shall apply: Bi, 1ppm (.0001%); Cd, 1ppm (.0001%); Fe, 10ppm (.0010%); Pb, 5ppm (.0005%); Mn, 0.5ppm (.00005%); Ni, 10ppm (.0010%); Se, 3ppm (.0003%); Ag, 25ppm(.0025%);S, 15ppm (.0015%); Sn, 2ppm (.0002%); Zn, 1ppm (.0001%).

Quick Links: